HiTec Tools Works is a professional in dealing of precision metal components and assemblies. Our services include product design, prototyping, production and assembly. We specialize in components and assemblies that meet exacting customer requirements. We have more than 7 years of experience in providing OEM solutions to a wide range of industries. Our experienced engineers, machinists, and technicians provide the highest quality products with the shortest lead times.

We are committed to meeting the most demanding customer requirements with the utmost degree of quality, on-time delivery and competitive pricing. With our advanced technology, experienced personnel and uncompromising commitment to excellence, HiTec Tools is the ideal partner for your most difficult manufacturing challenges.

Specialize in Cutting Tools, CNC Machines & Spare Parts, Machining Parts & Raw Materials for a wide range of industries, from medical device and aerospace to industrial and consumer goods. We provide the highest quality components, with a focus on customer service and quick turnaround times. We also offer a variety of secondary services, such as assembly, finishing, and testing, to ensure your parts are produced to your exact specifications.

With HiTec Tools, you will have access to a variety of CNC machining services as well as

secondary operations and assembly services to enhance your business operations. Secondary

operations are managed efficiently to produce accurate parts at competitive prices.

We are very proud of the fact that we are able to serve both small and large companies from a

variety of industries as our customers. As a customer-focused company, we take great pride in

the fact that we entrust our business to you.

We offer a wide range of services, including CNC machining, turning, milling, stamping, injection

molding, casting, and finishing. We work with common and exotic materials.

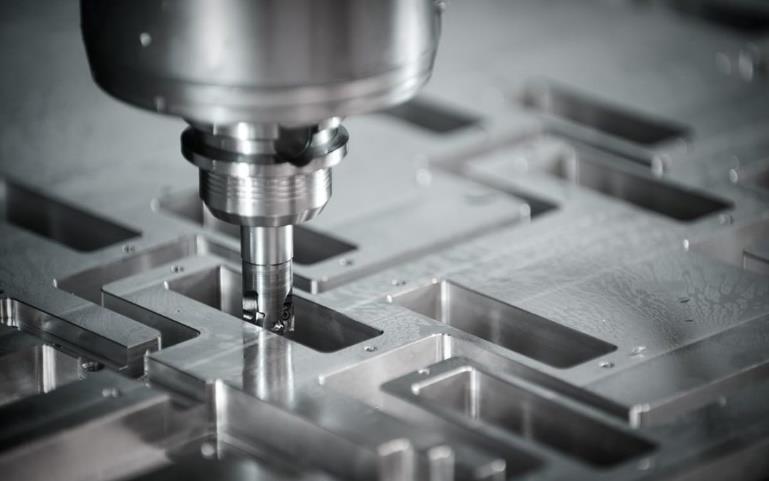

HiTec Tools offers 3-axis, 4-axis, 5-axis CNC

milling services for high-precision parts with

tight tolerances in a variety of materials,

including aluminum, alloy steel, stainless steel,

brass, and plastic.

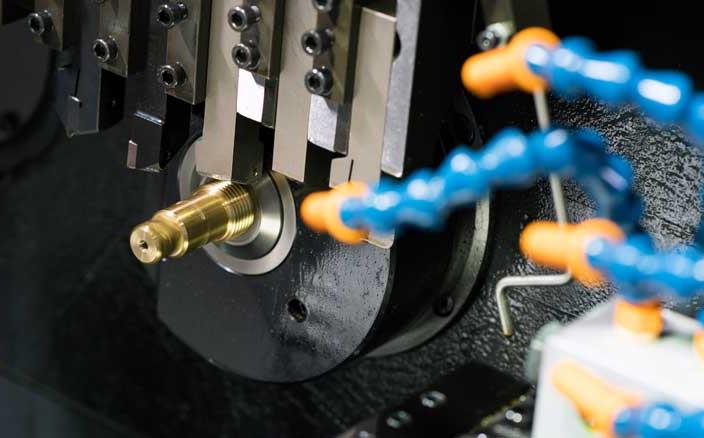

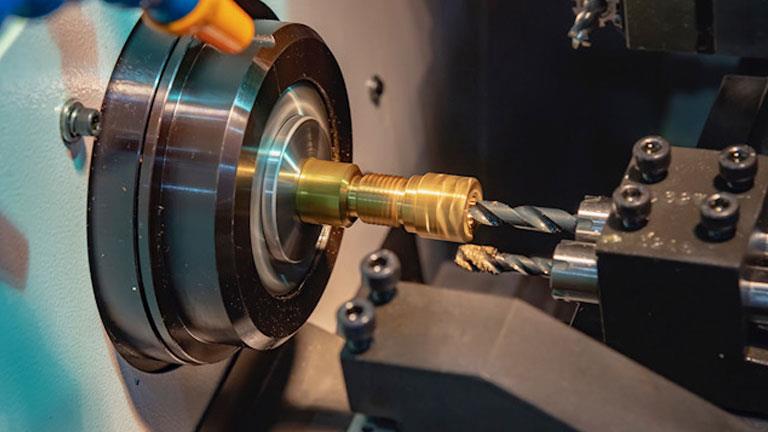

Swiss machining is a machining process that involves the use of a specialized type of lathe called a Swiss-type lathe. This type of lathe is designed to produce high precision parts with incredibly tight tolerances. The process is ideal for parts that need to be machined to exact specifications and is often used for watch and medical parts, nuts and bolts, and other small components.

Metal stamping is a process used to create shapes and parts from metal sheets. It is also known as press working and involves the use of a die and a press to form the metal into the desired shape. During the metal stamping process, the metal is placed between the die and press and then pressed into the die to produce the desired shape. The process can be used to make a variety of shapes and parts for .

Metal casting is a process in which molten metal is poured into a mold and allowed to cool and solidify. The casting process can produce a variety of shapes and sizes depending on the type of metal used, the shape of the mold, and the cooling process used. The metal casting process is used for a variety of products, from machine parts to sculptures.

Brass is an alloy of copper and zinc and is an ideal material for CNC cutting. It is strong, corrosion resistant, and has a long-lasting shine. CNC cutting can be used to make precision cuts for a variety of applications such as machine parts, jewelry, and musical instruments. The cutting can be done using various tools such as drills, end mills, routers, and laser cutters. The cutting process is often automated to ensure accuracy and consistency.

Aluminum CNC cutting is a process used to cut or shape aluminum using a computer numerical control (CNC) machine. CNC cutting utilizes a variety of tools such as end mills, drills, routers, lasers and plasma cutters to cut precise shapes out of aluminum. Aluminum CNC cutting is a versatile and economical way to fabricate a wide range of parts. It is used in a variety of industries such as aerospace, automotive, medical and electronics.

Metal forging is a process of shaping metal using localized compressive forces. The process involves the use of a hammer or press to shape the metal into the desired shape. Metal forging is done either hot or cold. In hot forging, the metal is heated to a temperature above its recrystallization temperature, which allows the metal to be more easily deformed. In cold forging, the metal is cooled below its recrystallization temperature to make it harder and easier to shape. The process of forging can be used to create a variety of shapes, such as bars, rods, and sheet metal.

An assembly line is a manufacturing process in which individual parts, components, or products are assembled together in a specific order to create a finished product. The process is often automated, with each part or component being added to the product in sequence. This type of manufacturing is used to increase production speed and efficiency, as the same sequence of steps is followed for each product. Assembly lines often feature specialized machinery and workers who are responsible for specific tasks.

HiTec Tools’ vision is to be the industry leader in offering consumers high-quality, innovative equipment and solutions that will help them achieve their goals and improve their lives. And mission to give clients the most cutting-edge, dependable, and affordable tools and goods available. In order to surpass client expectations, we work to uphold the greatest standards of quality, innovation, and customer service. We are devoted to becoming the go-to source for all of your tool and product needs and to giving our clients the greatest possible experience. We understand that every customer is different and has unique needs. We are dedicated to providing our customers with customized solutions that meet their individual requirements. Our engineering and manufacturing teams are highly experienced and are ready to help you get the results you need.

HiTec Tools’ management team collaborates closely to offer our customers the best goods and services. The team is made up of seasoned experts with deep expertise in each of their specialized domains. The team consists of representatives from a variety of divisions, including customer service, sales, engineering, marketing, production, procurement, and quality control. Each member of the team is dedicated to giving customers the finest possible service and highquality goods. We work hard to make sure that every one of our clients is happy with their purchases and gets the most for their money. While providing the greatest quality goods and services, we also work to keep our prices low.

Manufacturing, automotive, construction, aviation, and the medical fields are just a few of the industries served by HiTec Tools, a leading supplier of high-quality tools and equipment. HiTec Tools has more than 12 years of experience in the field and is committed to giving its clients the best goods and services possible. Our area of expertise is in creating tools and equipment especially for each client’s unique requirements. Each customer receives individualized attention from our team of skilled engineers and technicians as they develop the ideal solution for their project. Our dedication to excellence and craftsmanship guarantees the dependability and toughness of all of our tools and equipment. HiTec Tools are the greatest choice to give you the best quality tool at an affordable price, from hand tools to heavy-duty machines.

HiTec Tools is a prominent supplier of dependable and high-quality goods, services, and solutions for the industrial, commercial, and consumer markets. Since 2011, we have been offering our clients cutting-edge solutions, and we have amassed a wide range of goods, services, and options. Whole product ranges for the industrial, commercial, and consumer industries are among our main products. Our services and products are certified to meet industry standards and are created to satisfy the highest levels of performance, quality, and dependability. We’re dedicated to giving our clients the absolute greatest experience with our goods and services.

HiTec tools are an excellent method to show professionalism at work. Employers may make sure that their staff members are working successfully and efficiently by using such tools. Companies may make better decisions and boost productivity by utilizing these tools to make sure their data is structured and easily accessible. Finally, by utilizing HiTec Tools Works, businesses can make sure that their staff members have the resources necessary to perform their tasks effectively, which helps support a professional work environment.

1. Integrated tool with function of drilling, reaming and countersinking

2. Twist drill

3. Taper drill

Tools for machining composite materials (Milling tool)

1. Composite material milling tool A/B/C

2. Two-edge PCD end mill (Rough)

3. KEVLAR material milling tool

4. Two-edge PCD ball nose milling tool

Tools for Machining Aluminum Alloy (Milling tool)

1. PCD high speed milling tool

2. Carbide endmill

Honeycomb materials

1. lntegral ultrasonic disc tool

2. Straight edge ultrasonic tool

3. Honeycomb smashed milling tool (2 parts structure)

4. Honeycomb smash milling tool (3 parts structure)

Hard processing materials (Milling tool)

1. End mill (Titanium alloy machining)

2. PCD inserts (Titanium alloy machining)